1. Cultivation

It takes about five years from planting the tea plant to harvesting to produce a cup of tea.

In preparation for the first tea of spring, the soil is prepared and the tea leaves are carefully cared for from the previous year, and the harvest is finally complete. The tea plants are carefully grown in the rich natural environment of Kirishima, and are kept healthy to produce high-quality tea leaves. The tea leaves grown in this way form the foundation for the subsequent tea processing and production processes, resulting in delicious tea.

2. Harvesting

Imamura Tea Farm has a vast tea field that is roughly the size of four Tokyo Domes, where tea leaves are carefully harvested throughout the year. Starting with the first harvest in April, the second and third harvests are picked in summer, and the rich tea leaves are picked in autumn and winter. This meticulous work throughout the year gives each and every tea leaf a special value.

Kagoshima Prefecture accounts for 44% of Japan's total production of third and subsequent harvest tea, and the natural blessings of the Kirishima soil and the passion of the tea producers continue to support Japan's tea culture.

At Imamura Tea Farm, we pay careful attention to the timing and method of harvesting, bringing out the unique characteristics of each season's tea leaves to the fullest. The first tea picked in spring is fresh and fragrant, while the tea leaves harvested in autumn and winter are strong and full-bodied, allowing you to enjoy different flavors for each season.

The harvested tea leaves are further refined in the subsequent manufacturing and processing steps, transforming into a cup of blissful flavor. Please enjoy this exquisite tea that combines the nature of Kirishima with the skill of artisans.

Manufacturing and Processing

After harvesting, each step, such as manufacturing, processing, and roasting, is carried out one by one to produce the finest tea.

We see tea growing as a creative expression, not just a farming or manufacturing process.

We sharpen our senses of color, taste and smell to appreciate the natural blessings of Kirishima that are contained in each and every tea leaf.

How can we express this and deliver it to people? We continue to explore these possibilities every day.

We deliver tea that is truly delicious, with the spirit of wabi-sabi that connects people together while having a conversation with the tea.

4. Steaming process

The steaming process is an important step that determines the color, flavor, and aroma of tea leaves. A difference of just a few seconds in steaming time can have a significant effect on these characteristics. Depending on the degree of steaming, tea leaves are classified as deep steamed (Fukamushi) or shallow steamed (Asamushi). After the steaming process, the tea leaves are cooled and move on to the next process.

5. Check and adjust

The steaming process stops oxidation and preserves the bright green color of the tea leaves. For Sencha, steaming time is usually around 30 seconds, but longer steaming times will deepen the color and flavor. This critical stage determines the final color, aroma, and taste. Since a single mistake can affect all subsequent steps and the final quality of the tea, meticulous checks and adjustments are made.

6. Rough kneading

The steamed tea leaves are immediately cooled to preserve their flavor and aroma. If they are left at high temperatures, their quality will deteriorate. After cooling, a rough rolling machine is used to remove excess moisture from the steamed tea leaves. The leaves are then transferred to a rough rolling machine where they are rolled under strong pressure and dried with hot air.

7. Kneading

Rolling is a process in which pressure is applied to the tea leaves to distribute the moisture evenly. The choice between strong and gentle rolling has a significant impact on the flavor, aroma, and shape of the tea. Gentle rolling allows the tea leaves to maintain their shape while gradually bringing out the flavor, making this process essential in shaping the tea's individual characteristics.

11. Color selection

Tea leaves are sorted using high-precision cameras to detect minute impurities and color differences that cannot be detected by the human eye. Until the 1930s, in tea factories, women known as "senriko" were responsible for removing the stalks from the tea leaves by hand and turning them into products.

12. Combination

Blending is a technique for blending various tea leaves to create a harmonious flavor. It involves identifying the characteristics of each tea leaf, such as the variety and steaming level, and using sight, smell, taste, and touch. This technique requires skill and experience, and is an important process for creating the ideal cup of tea.

13. Roasting

We use two drum-type roasters to roast the rough tea so that its moisture content is kept between 5% and 2%. To avoid burning or a green smell, we use our keen sense of smell to distinguish between different flavors and adjust the heat accordingly. The temperature is adjusted between 100℃ and 130℃. The outside air conditions also have an effect, so we avoid roasting on rainy days. When all the conditions are in harmony, a sweet, fragrant tea is completed.

14. Packaging

The finished tea is immediately packaged in designated quantities to maintain quality. It is then prepared for shipment and sent to the Kagoshima Tea Market for sale. Each large bag contains 30kg of tea leaves. It is also packaged in a form suitable for retail sale, and the individually wrapped products are delivered to customers.

Imamura Tea & Kagoshima Highlights

Imamura Tea Farm and Kagoshima Tea

Kagoshima Prefecture is one of Japan's leading tea-producing regions and is widely known for its size and outstanding quality.

Imamura Tea Farm has tea fields covering a total area of 200,300 m2, and cultivates tea in harmony with the rich natural environment of the area.

Plantation's total field area

Kagoshima's rank

Kagoshima's raw tea output

Third harvest production

Kagoshima Prefecture is the second largest tea producer in Japan, with an annual production of 26,700 tons. In particular, the prefecture's production of tea from the third harvest onwards accounts for 44% of the national total. Traditions and techniques to maximize the potential of tea leaves in each season have been handed down.

At Imamura Tea Farm, we treasure the blessings of Kagoshima's nature and its rich tea culture, and deliver high-quality tea to everyone. Our tea farm preserves tradition while looking to the future, and we put our heart and soul into making tea, one leaf at a time. Please enjoy a cup of tea filled with the power of the Kagoshima earth and our passion for tea.

Certifications and Qualifications

Certifications and Qualifications

Imamura Tea Farm delivers high-quality, safe tea through rigorous certifications. We have obtained ASIAGAP certification, which indicates proper management of tea production and processing, and JAS organic certification, which complies with Japan's JAS organic standards. These certifications reflect our commitment to sustainable agriculture, environmental friendliness, and consistent quality. As a tea farm trusted around the world, we strive to deliver tea that can be enjoyed with peace of mind.

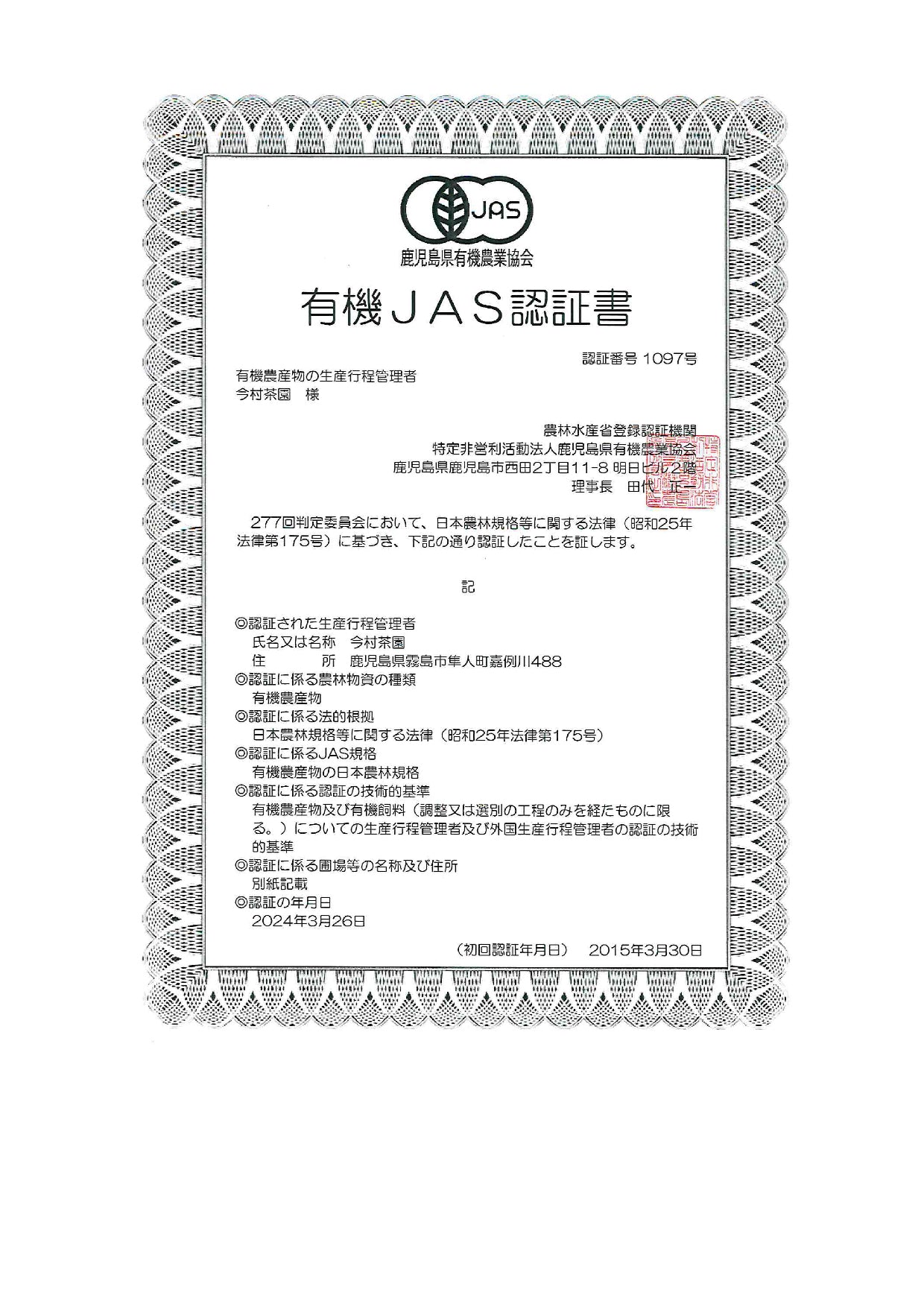

有機農産物

Organic Agricultural Product Process Manager

Certification Number: 1097

- Type of Agricultural Products Subject to Certification

Organic Agricultural Products - Legal Basis for Certification

Act on Japanese Agricultural Standards (Act No. 175 of 1950) - JAS Standards for Certification

Japanese Agricultural Standards for Organic Agricultural Products - Technical Standards for Certification

Technical Standards for Certification of Organic Agricultural Products and Organic Feed (limited to those that have introduced processes such as sorting or selection only) for Production Process Managers and Overseas Production Process Managers

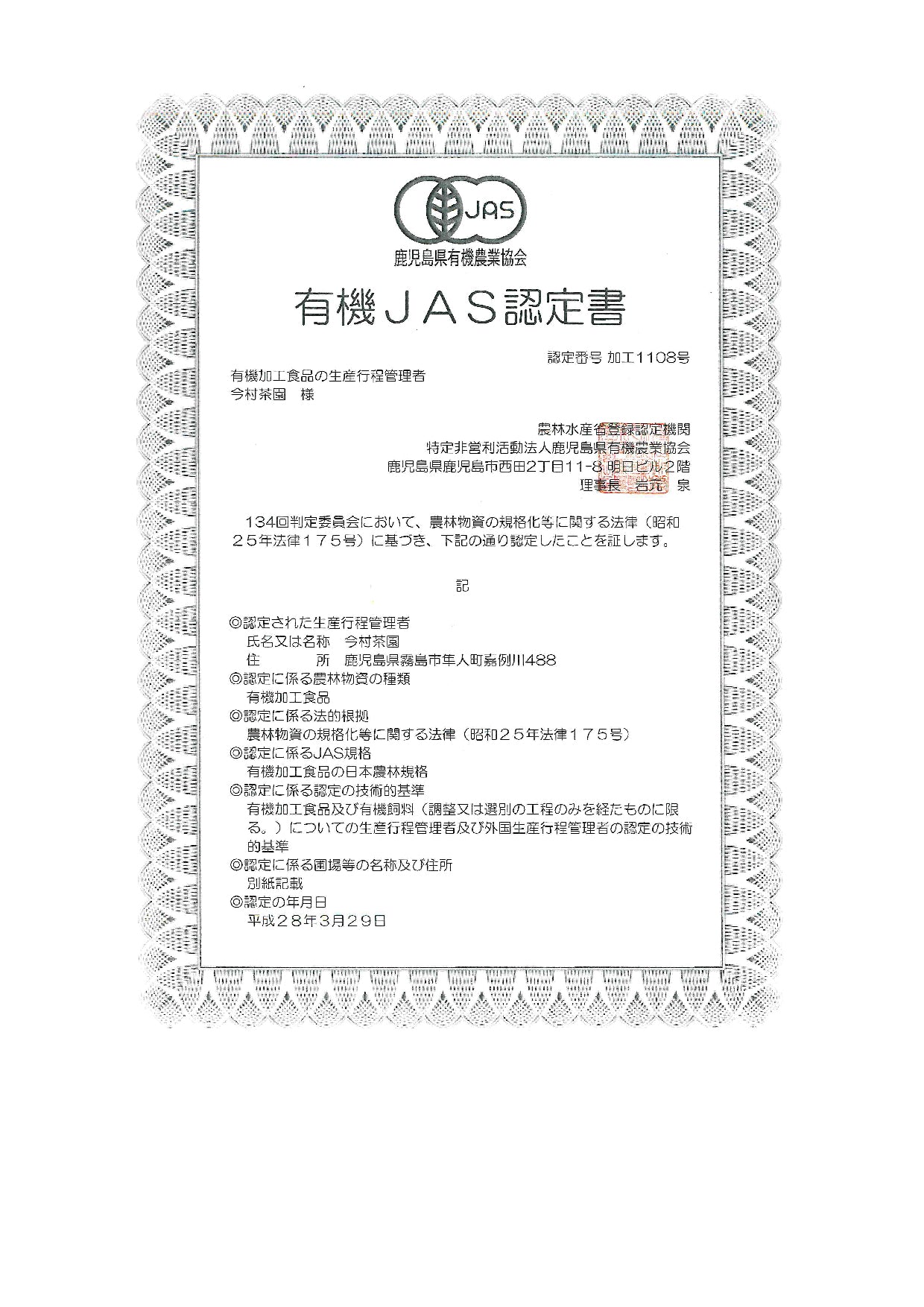

有機加工食品

Organic Processed Food Production Process Manager

Certification Number: Processing 1108

- Type of Agricultural Products Certified

Organic Processed Foods - Legal Basis for Certification

Act on Japanese Agricultural Standards (Act No. 175 of 1950) - JAS Standards for Certification

Japanese Agricultural Standards for Organic Processed Foods - Technical Standards for Certification

Technical Standards for Certification of Organic Processed Foods and Organic Feed (limited to those that have introduced processes such as sorting or selection only) for Production Process Managers and Overseas Production Process Managers

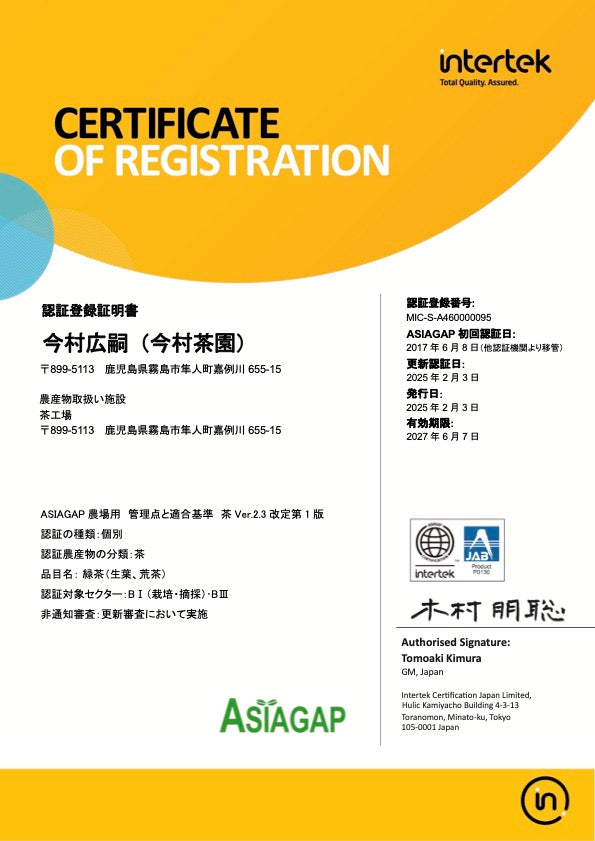

ASIAGAP

CERTIFICATE OF REGISTRATION

Certification Number: MIC-S-A60000095

- Standard

Farm Management and Compliance Standard for Tea, Version 2.3 (Revised Version 1) - Certification Type

Individual Certification - Product Category

Tea - Products

Green Tea (Raw Leaves, Unrefined Tea) - Certified Scope

BI (Cultivation and Harvesting)

BIII (Processing)